SHARE THIS POST

Optical bonding is a type of integration service that is used to laminate a touch screen or other rigid material to the top surface of an LCD. The bond is created by dispensing and then curing a form of optically clear adhesive between the touch screen and display creating a permanent bond with no air gap between the two components. There are many advantages to the optical bonding method of integration vs traditional perimeter gasket attach methods, one of the most notable being the enhanced performance. Here are the top 5 benefits every innovative company should know, with an inside look at choosing the right adhesive and which industries are the most suited for an optically bonded display.

Air Bonding Vs. Optical Bonding

Traditionally, touch sensors or other rigid materials are bonded to the display with adhesive tape that is only applied to the edges. This process is referred to as “air bonding”. This creates a detrimental air gap that weakens the LCD display, distorts imagery in sunlight, traps impurities that shorten the life of the display, and much more. Optical bonding is the process of attaching a glass/plastic/filter substrate or touch panel to an LCD module. Liquid optically clear adhesive (LOCA) is placed between the cover substrate and LCD to completely fill the air gap. The assembly is cured via a UV-light process that fixes the display/substrate together while solidifying the gel, creating an optically brilliant and ruggedized display solution.

1. ) Achieve Clarity and Viewability

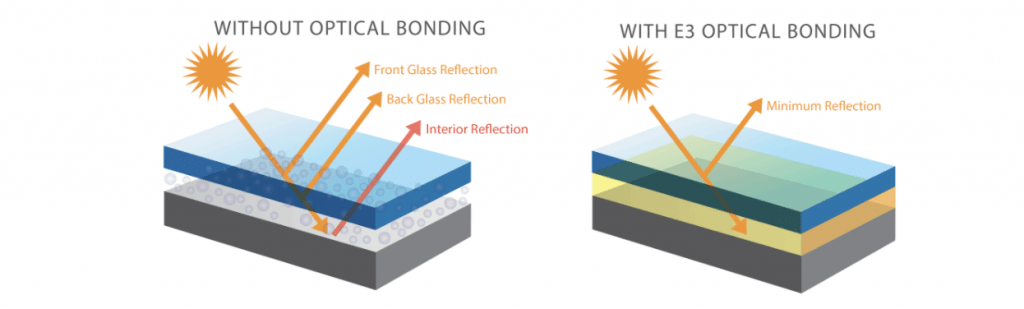

Optical bonding eliminates the internal reflection between the LCD and the cover glass or touch screen because the bonding process creates a single index of refraction. Reducing internally reflected light loss increases display contrast and viewability. Improved display contrast enables displays to be more readily seen in bright ambient conditions, without increasing backlight brightness and the associated unwanted higher power and higher operating temperatures.

2.) Maximum Protection

Optical bonding dramatically increases both physical durability and impact resistance. Unlike traditional, unprotected LCDs, optically bonded displays can have a cover glass that protects the display from rain, dust, snow, hammers, screwdrivers, etc. This not only helps a display withstand the elements but also makes the LCD cover glass vandal-resistant. Adding custom cover glass, touch screens, optical filters, optical coatings, and other enhancements with optical bonding creates a durable and complete rugged solution. Optical bonding is an effective solution for improving resistance to shake and shock environments – a benefit especially useful in harsh military and avionic environments. A rugged display is one that will last and reach full-term life expectancy.

3.) Dust and Moisture Prevention

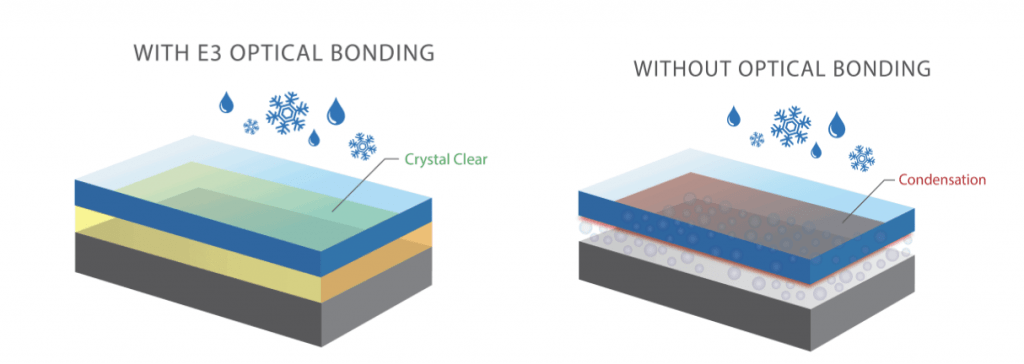

Traditional touch screen configurations are only bonded from the sides and leave a massive air gap in the middle that can allow dust, dirt, and moisture to get in and destroy the display from within. The optical adhesive fills the gap between the substrate layer and LCD, preventing contaminants from impacting the display viewability. Water and electronics just simply do not mix and condensation or impurities can render the display unreadable. This advantage is especially important in maritime environments where displays are often exposed to harsh saltwater.

4.) Accurate Touch Experience

For LCDs with touch sensors attached, the touch sensor cover lens thickness influences touch accuracy and can affect usability with both touch pens and bare hands. Air bonded solutions that require high levels of durability typically require thicker cover lenses which can impact touch performance. Optically bonding the touch sensor to the LCD maintains maximum durability with thinner cover lens materials thus maintaining or increasing touch accuracy. When a display has a more accurate touch experience, it can be used more efficiently in fast-paced environments.

5.) Improved Heat Dissipation

Heat dissipation is a key element in measuring display performance. The heat generated by the operation of the display is dissipated through optical material and is not blocked by insulating air layers. By filling the insulating air gap between the components, heat can be transferred to the outside environment. The improved heat dissipation also increases the LCD display’s solar aging performance. Improved heat dissipation can decrease display solutions thickness because the need for cooling fans or other similar features is eliminated.

Which Industries are Most Suited to Optical Bonding?

Optical bonding is popular among the military, marine, medical, transportation, and retail sectors whereby a higher-performing display is required due to the harsh environments. Optical Bonding is suited to industries that tend to use rugged displays in high-reliability environments or industries where displays need to be seen in high ambient light conditions. The process of Optical Bonding is particularly well suited and much more effective when applied to devices that operate outdoors or in heavily lighted environments. When LCD displays are manufactured, including touchscreens, the front glass of the screen is layered onto the LCD module. This doesn’t present a problem in standard viewing environments, however in certain conditions, like with outdoor placement, the tiny gap between the 2 layers can impair viewing performance.

Choosing the Right Adhesive with E3 Displays

After knowing the advantages of optical bonding using liquid optically clear adhesives, it’s important to know the different types of adhesives that can be used. Some silicones can be cured using UV rays or there are acrylates that are typically cured using a combination of light and humidity. Both deliver excellent optical clarity but in most cases, silicones are considered the preferred adhesive. Silicones are smoother and are less likely to create image defects called “Mura effects”. After careful evaluation of numerous commercial materials (silicones, epoxies, urethane acrylates), E3 Displays determined that while UV curable urethane acrylates offered distinct mechanical and process advantages over silicones and epoxies, these commercially available adhesives did not meet the technical performance criteria essential for use in the harsh environments of avionics and military products. To solve this issue, E3 developed a family of custom adhesive formulations whose overall performance exceeds that of competing materials and are tailored to meet varied product requirements. After thousands of hours of development and testing, E3 Displays has created unparalleled adhesives in optical bonding which are application (and display) specific. The results of competitive testing by a variety of customers in a wide range of applications are overwhelming – E3 Displays consistently outperformed competitive products in all facets of evaluation. E3 Display bonding technology delivers the best value to its customers and ensures long term product reliability.

Optically Bonded Overlays

Optically bonded displays have the potential for enhancement overlays to improve the overall performance and quality of the display. These include but are not limited to:

Anti-Vandal Shields

These rugged filters are available in various sizes to protect your optically bonded displays from impact, scratches, and chemicals. These shields provide maximum protection without sacrificing the anti-glare features, light transmission, and durability. These substrates are typically composed of polycarbonate, acrylic, chemically strengthened glass, or thick glass.

EMI/RFI Shields

EMI is known as electromagnetic interference which is a disruption from another source. EMI is also referred to as Radio Frequency Interference (RFI). EMI happens when the operation is in close proximity to a device that emits signals. E3 Displays offers EMI protection integrated into LCD screens which deter outside magnetic interferences. No matter what industry you operate in, you want to have the security of knowing that you have a reliable display screen that performs with no interruptions.

Heaters

In cooler climates, the LCD fluid will slow down and change the response time of the display. E3 can install transparent heater films through optical bonding to maintain a sleek and modern display, as well as maintain display response time.

Touch Sensors

Touch sensors allow the user to interact with their devices in a more efficient and captivating way. E3 Displays can create various optically bonded touchscreens including multi-touch, projected capacitive, and resistive.

Conclusion:

The key to maximizing your display value and performance is through liquid optical bonding, which is achieved by filling your display air gap with an E3 custom liquid optically clear adhesive. Optical Bonding provides many benefits including, enhanced clarity and viewability, ruggedization, dust and moisture protection, accurate touch experience, and improved heat dissipation. E3 Displays can optically bond any display type, up to 100”. There are also various overlays and enhancements that can be installed including, anti-vandal shields, EMI-RFI shields, heaters, and touch sensors. Optical bonding is the best way to achieve advanced clarity and maximum durability.

About E3 Displays:

We’re a global design and manufacturing company that helps the world’s most innovative companies define the future of their business display needs. With over 20 years of combined experience in display technology, E3 Displays has everything you need to develop and manufacture your custom touch display all in one place. With customer-centric solutions featuring strategic planning, competitive pricing, longevity, and support, we ensure the best products on the market to help you scale. In the end, displays are a centerpiece in any hardware that provides a very important visual message in your product. We want to ensure that the visual entity exceeds your optical and performance requirements.

Submit your project information

Submit your project information Speak with an expert display advisor

Speak with an expert display advisor